- Home

- Recent news

- News details

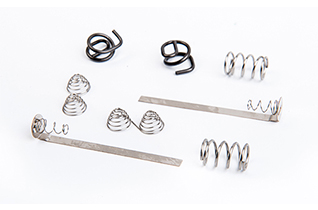

Explanation of common spring terms

1. Opening and grinding at both ends: after "opening not grinding", the port grinding operation is added. One strand is only applicable to large spring and two spring sets

2. Helix: the helical shape (open or closed) of compression, extension, and torsion springs

3. Torque: a twisting action in a torsion spring that produces a turning effect equal to the load multiplied by the distance from the point of load to the shaft of the spring lift (torque arm), usually expressed as n mm, lb in, or LB ft.

4. Close body: winding to make adjacent coils contact

5. Shot Peening: a kind of cold treatment process. In this process, the surface of the material is strengthened by high-speed shot peening, forming compressive stress on the spring surface, so the fatigue life can be improved

6. Torque: torque divided by arm length equals torque.

7. Natural frequency: when the closing is fixed, the natural free vibration frequency of the spring itself (usually expressed as the number of vibrations per second). The working frequency of the spring should not be higher than 1 / 10 of its natural frequency, otherwise it is easy to form resonance and lead to early fatigue.

8. Perpendicularity: the angle difference between the central axis of the compression spring and the vertical plane of the necking

9. Perpendicularity when applying load: similar to "perpendicularity", the difference is that the spring is under load.

10. Winding ratio: the ratio of the pitch diameter of the coil spring to the material. The ideal winding ratio of the spring is 7-16

11. Press and height: compress the compression spring to the spring height when each circle contacts.

12. Buckling: bending or lateral deflection of a spring when it is compressed, related to the ratio of height to diameter (L / D)

×

×